MODERN

TEXTILE

solutions.

At UTG, we use the latest technology in digitization, including 3D – not only to make great show cases, but as an active tool we use every day for Digital Product Creation.

At UTG, we use the latest technology in digitization, including 3D – not only to make great show cases, but as an active tool we use every day for Digital Product Creation.

The technology is fast moving and is going to be an important part of a more sustainable clothing industry. Using 3D improves the speed of both sampling and the actual productions porcesses greatly. Samples can be made ready within hours thanks to our 3D tools.

We have a vision to reduce the number of physical samples, by using 3D technology when producing our designs. In this way, we help reduce CO2 emission in both designs, fitting and production processes. Also, by using these digital solutions, we help minimize the amount of garment that never reaches the consumers.

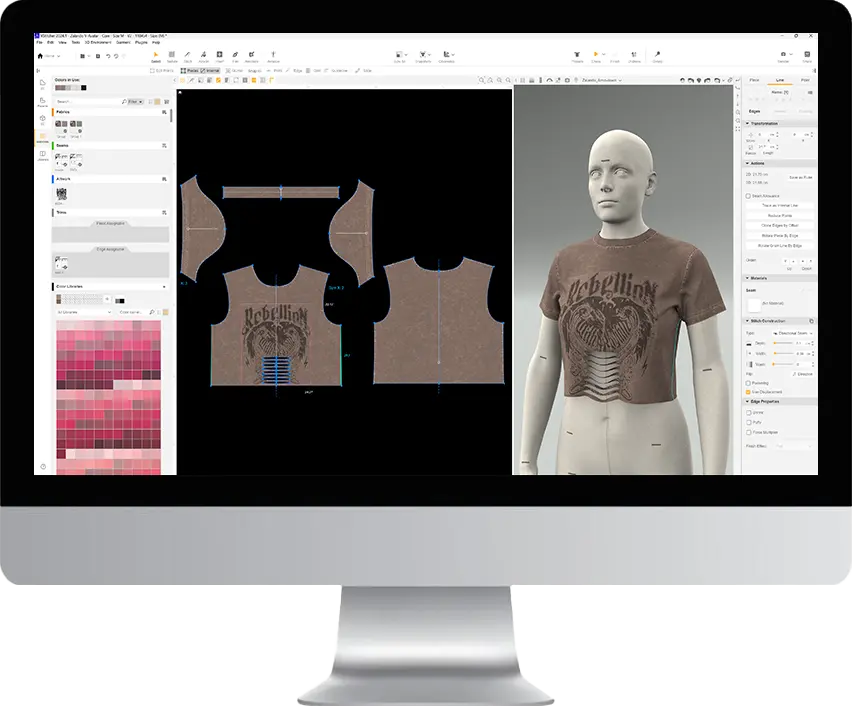

In the clothing industry, initial sketches are widely utilized as a foundation for design. However, individual interpretations of these sketches can vary significantly, leading to diverse expectations regarding the final product. By employing 3D modelling to create the first prototype, we can accurately visualize the intended style. This approach allows for easy adjustments—such as changing colours, trimmings, altering length, or modifying fit—ensuring that the final result aligns with the product.

Utilizing advanced 3D software, we can present prototypes in a multitude of formats that enable a highly realistic representation. This technology allows us to emphasize all details, including the physical properties of fabrics and material visualization. By zooming in further, we can effectively highlight essential elements such as seams, trims, creases, and other design features. This level of detail not only enhances the visual appeal of the prototypes but also facilitates a comprehensive understanding of the garment’s construction and functionality. Ultimately, this approach supports the decision-making throughout the design process, ensuring that the final product aligns with both aesthetic and practical expectations.

Great fit makes your customers come back.

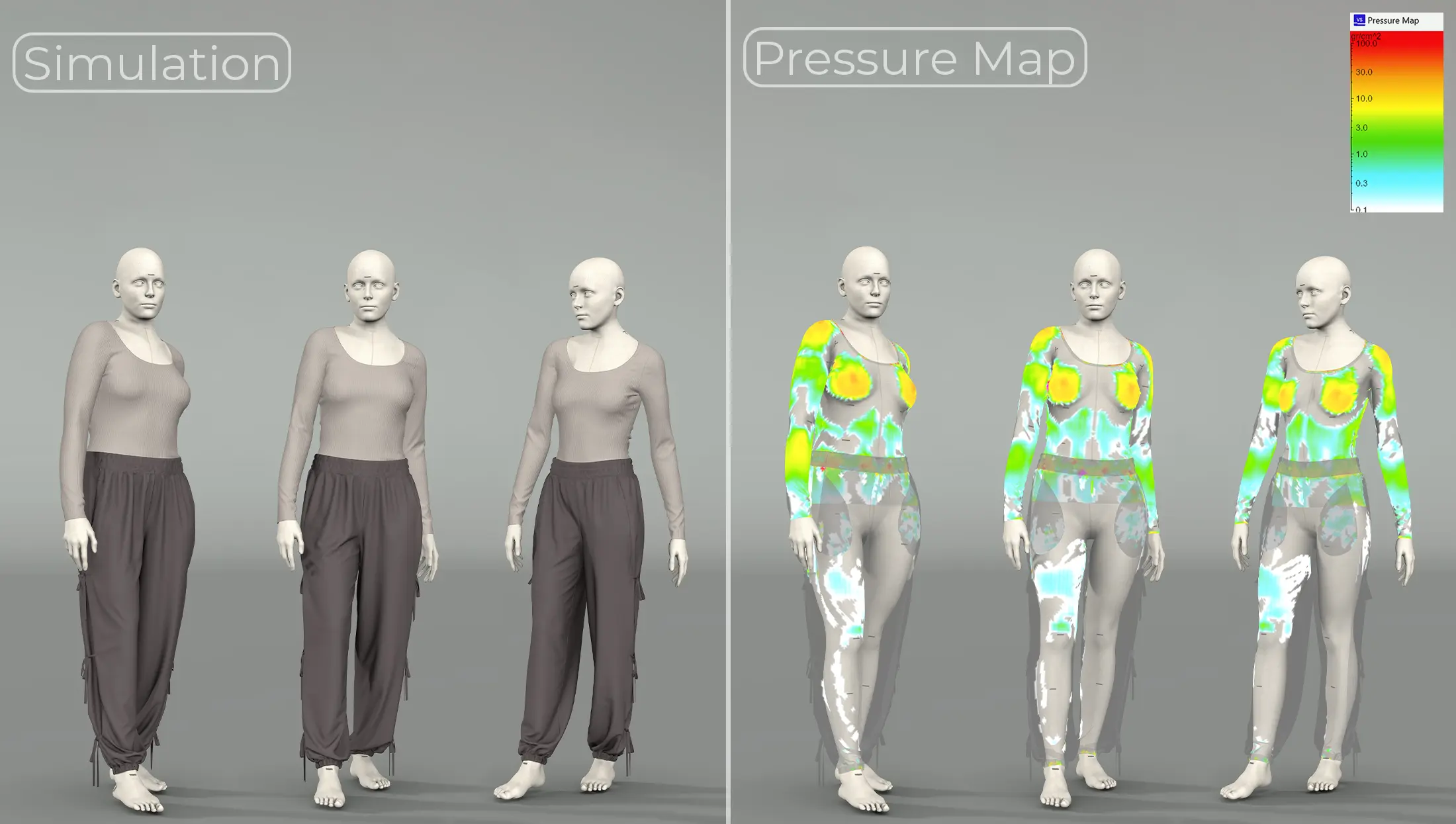

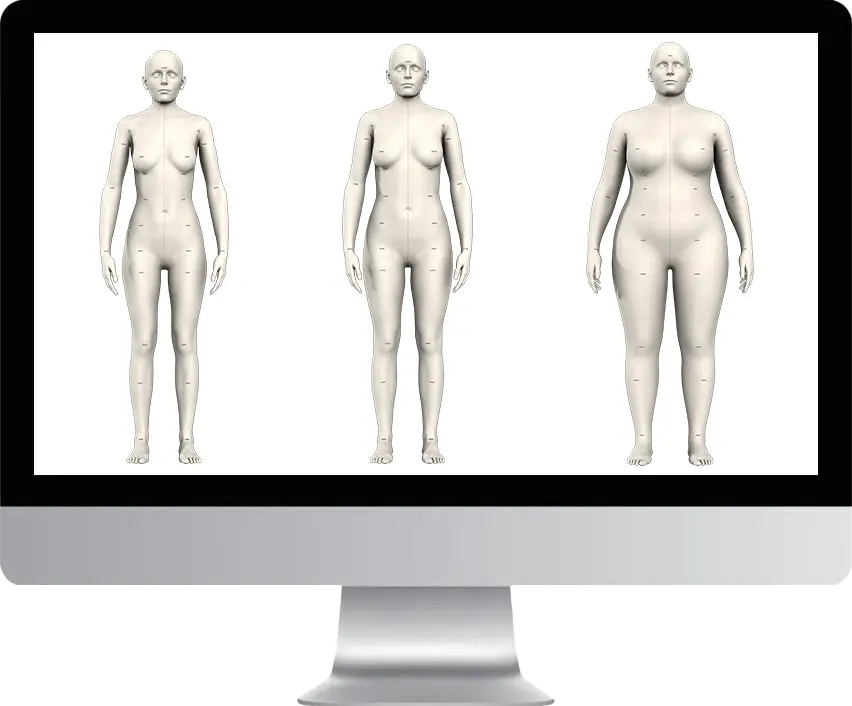

We help to intergrate your companies sizes into 3D fitting models. This enables us to do 3D fittings in real life size. This saves time, and fitting samples. With these fittings we can for example avoid grading mistakes as you can see the fit instantly on your avatar size set.

When the 3D proto sample is in place, it is fast to see what prints look nice on the garment and easy to add different colors or prints to see what works in your collection. Does it look nice online? The decision is way easier to make based on a true to life image. We already have customer who knows the shape, fit and the quality of the styles they want, and they can decide the color or prints within hours being faster at placing orders for the coming season. This saves a lot of days waiting to see a physical sample and save the world for loads of samples that no one will ever wear.

possibilities with

See how the 3D program works in real life on the screen and get an idea of the time samples saved by using this technology. Watch our Webinar in English here.

A part of Red Cross Corporate Club.